DOSING TECHNOLOGY FOR GRANULATE

Our loss-in-weight feeders are suitable for pellets, fibres, grinded materials, micro-pellets or polymer-powders. Our volumetric feeders MONO, LOGO, SOLO und GOLO can be converted into our gravimetric feeders MODUS, ECONO, RATIO and GOLIA by linking the feeder to a platform scale. The output of the feeder is determined by the choice of the gear, discharge pipe and screw.

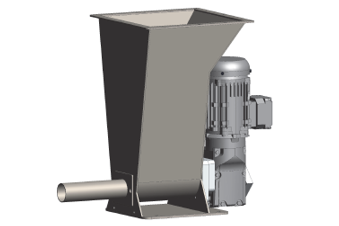

LOGO

Single-screw feeder

- Cost effective solution for good flowing solids

- Removable motor/ screw unit

- Extensive modular hopper system

- Easily dismantled, without unecessary parts

ECONO

Loss-in-weight feeder

LOGO + BASIC platform scale

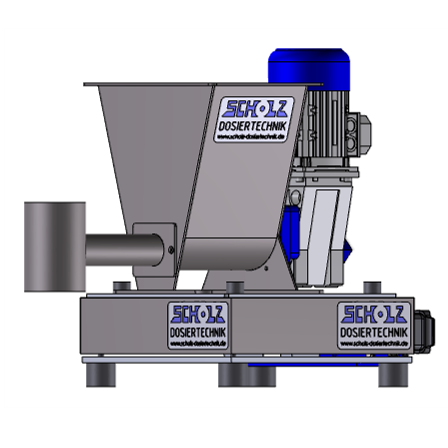

MONO

Single-screw feeder

- Cost effective solution for good flowing solids

- Comparable to LOGO, just more powerful

- Removable motor/ screw unit

- Extensive modular hopper system

- Easily dismantled, without unecessary parts

MODUS

Loss-in-weight feeder

MONO + BASIC platform scale

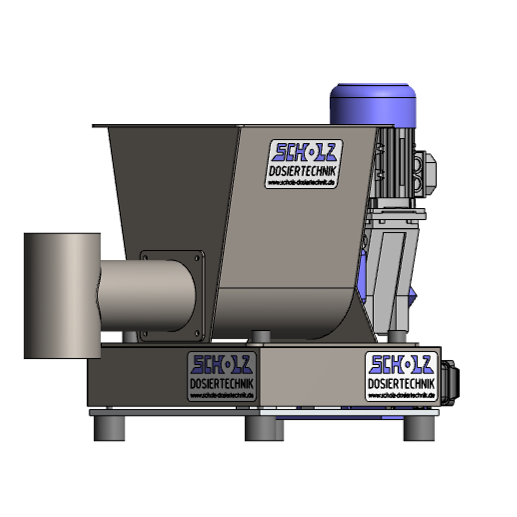

SOLO

Single-screw feeder

- Cost effective solution for high dosing capacities

- Proven many times for regrind, recycling material etc.

- Extensive modular hopper system

RATIO

Loss-in-weight feeder

SOLO+ BASIC platform scale

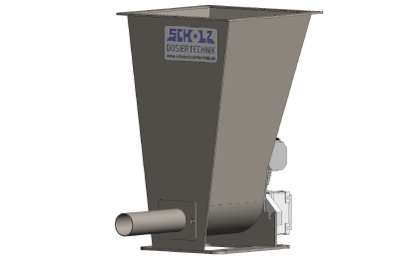

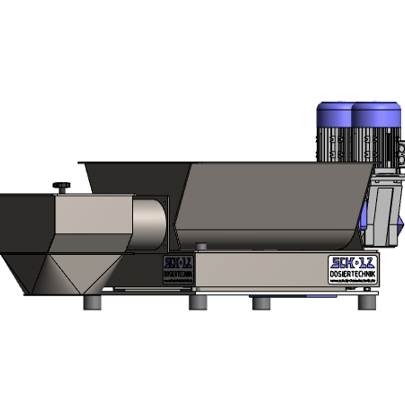

GOLO

Twin-Screw feeder

- Cost effective solution for high dosing capacities

- Proven many times for regrind, recycling material etc.

- Extensive modular hopper system

GOLIA

Loss-in-weight feeder

GOLO + BASIC platform scale

DOSING TECHNOLOGY FOR POWDER

Our differential feeders, single screw feeders with flexible polyurethane trough and separate paddle motor, are suitable for heavy flowing powders, regrinds, microgranulates and fibers. Our volumetric feeders FLEX50, FLEX80 and FLEX130 can be converted to our gravimetric feeders VARIO, SOLID and TITAN by linking them to a platform scale.

FLEX50

Single-screw feeder

- Separate paddle-drive

- Flexible adjustable paddles (stroke, distance, size)

- PU-hopper with stable frame for easy handling

VARIO

Loss-in-weight feeder

FLEX50 + BASIC platform scale

FLEX80

Single-screw feeder

- Separate paddle-drive

- Flexible adjustable paddles (stroke, distance, size)

- PU-hopper with stable frame for easy handling

SOLID

Loss-in-weight feeder

FLEX80 + BASIC platform scale

FLEX130

Single-screw feeder

- Separate paddle-drive

- Flexible adjustable paddles (stroke, distance, size)

- PU-hopper with stable frame for easy handling

TITAN

Loss-in-weight feeder

FLEX130 + BASIC platform scale

TWIN20

Twin-screw feeder

- Suitable for sticky, dull as well as very light additives

- Available with twin motorisation for heavy metal powders

- With horizontal agitator

- Removable front and rear plate for easy cleaning

DUPLO20

Loss-in-weight feeder

DUPLO20 + BASIC platform scale

TWIN40

Twin-screw feeder

- Suitable for sticky, dull as well as very light additives

- With twin motorisation for heavy metal powders

- With horizontal agitator

- Removable front and rear plate for easy cleaning

DUPLO40

Loss-in-weight feeder

DUPLO40 + BASIC platform scale

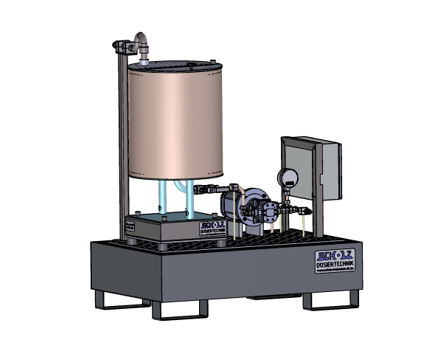

DOSING TECHNOLOGY FOR FLUIDS

Our loss-in-weight feeders are suitable for fluids, for example oils, softener, silanes, water, waxes, silicones and glycerines. The feeders are designed for outputs of 0,1 - 1000kg/h, viscosity of 0 - 100000mPas, pressure up to 200bar and heat up to 160°C. The feeders are available as mobile units. Depending of the use, a diaphragm, gear, hose or piston pump is used.

WEIGHING TECHNOLOGY

By linking a platform scale, volumetric gravimetric dosing devices are created. All of our platform scales have an identical height. We offer two different measurement techniques, the PESA string technique and the strain gauge technique (DMS). Depending on your capacity requirements, the feeder will be linked to a SCHOLZ BASIC 300, SCHOLZ BASIC 400, SCHOLZ BASIC 600 or SCHOLZ BASIC 800.

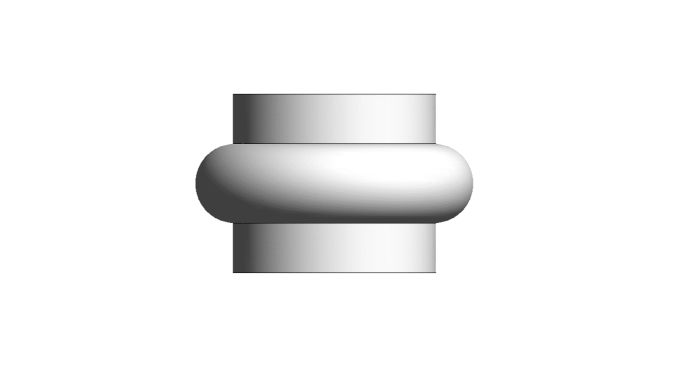

PESA-STRING-TECHNOLOGY

The tension of a vibrating string is influenced by the load weight on the platform scale, which changes the vibration frequency. The weight is determined from the change in the oscillation frequency. The technology is used for gravimetric feeders with SCHOLZ BASIC300, SCHOLZ BASIC400 and SCHOLZ BASIC600.

DMS-TECHNOLOGY

The measuring principle is based on the change in electrical resistance when suitable materials are stretched and compressed. The load on the platform scale thus causes a voltage change by which the weight is determined. The technology is used for batch applications as well as gravimetric applications with SCHOLZ BASIC700.

GRAVIMETRIC EQUIPMENT

We offer accessories for gravimetric dosing devices. The folding and step bellows as well as the pipe caps, filter bags and hose clamps are particularly easy to maintain as they can be easily replaced.

AVAILABLE CERTIFICATIONS

Explosion-proof version:

ATEX certified

Food-safe version:

FDA - EC 19535/2004 certified

YOUR CONTACT PERSONS

Gerhard Scholz

Alexandra Scholz

Gerd Scheidemantel

Frank Nikolaus

Raphael Stürmer

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.