DOSING TECHNOLOGY

Solutions for granulate, fibers, regrinds, powders and liquids

All dosing devices can be operated either in volumetric or gravimetric mode: for some applications it is sufficient to simply operate the device on a frequency converter. This makes it possible to achieve sufficiently high levels of accuracy, depending on product properties such as compressibility and flow behavior. If more precision is required, the dosing device is placed on a platform scale and connected to our gravimetric controller. Compliance with the recipes is constantly monitored and changes are responded to immediately.

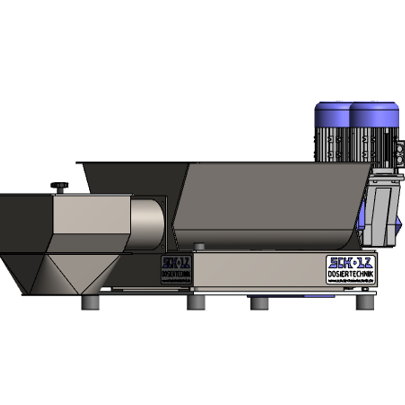

GRANULATE

Our basic line with the LOGO, MONO+, SOLO and GOLO models is ideal for well-flowing granulate. There is no unnecessary technolody added - this ensures an unbeatable price! Furthermore, equipped with an agitator, they are tried-and-tested solutions for regrind, foil scraps and recycled materials of all kinds.

LOGO

Single screw

12-60mm

1 until 500 kg/h

- Basis line

- Inexpensive

ECONO

Loss-in-weight feeder

LOGO + BASIC platform scale

MONO+

Single screw

12-60mm

until 1.000 kg/h

- Powerful engine

- Extras available

MODUS

Loss-in-weight feeder

MONO + BASIC platform scale

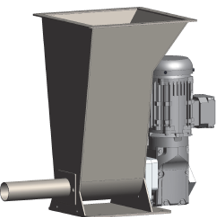

SOLO

Single screw

40-100mm

until 5.000 kg/h

- Specialist for recycling

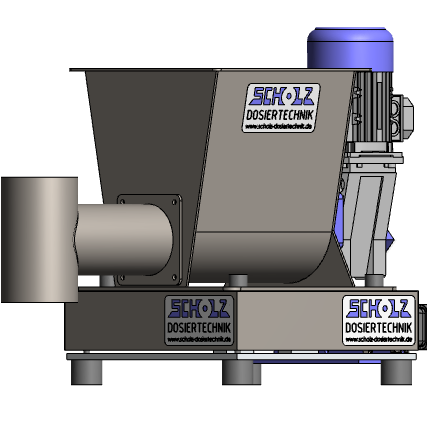

RATIO

Loss-in-weight feeder

SOLO + BASIC platform scale

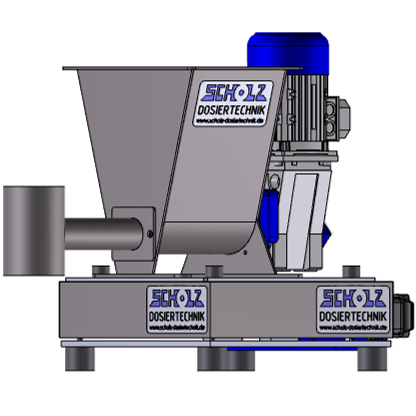

GOLO

Single screw

40-100mm

until 10.000 kg/h

- For lightweight fabrics

GOLIA

Loss-in-weight feeder

GOLO + BASIC platform scale

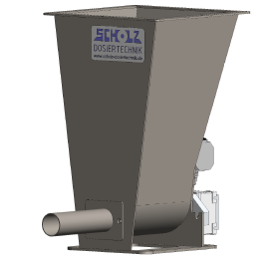

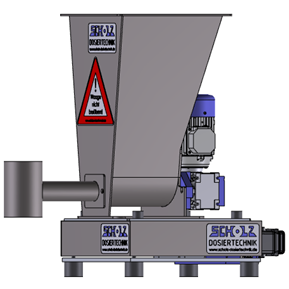

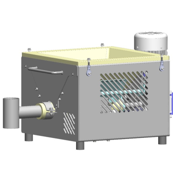

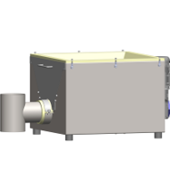

POWDERS

Our FLEX feeders are equipped with two motors. This allows you to regulate the paddling frequency of the flow aid separately if necessary. This model series is the newest generation of FLEX feeders on the market and impresses with its extremely robust mechanics and paddles that can be adapted to various requirements. We are happy to forego maintenance-prone constructions such as eccentrics and bicycle chains that you find with our competitors! Another practical detail: Our PU trough is easily removable and has a cast metal frame which greatly simplifies handlung and reinserting the through after cleaning.

FLEX50

Single screw

13-40mm

1 until 100 kg/h

- For pigments, flame retardant

VARIO

Loss-in-weight feeder

FLEX50 + BASIC platform scale

FLEX80

Single screw

31-75mm

until 1.000 kg/h

- For mineral fillers

SOLID

Loss-in-weight feeder

FLEX80 + BASIC platform scale

FLEX130

Single screw

100-125mm

until 10.000 kg/h

- Large product room/ funnel

TITAN

Loss-in-weight feeder

FLEX130 + BASIC platform scale

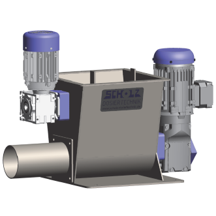

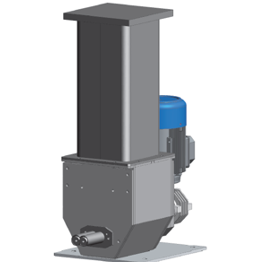

ADDITIVES

Our TWIN feeders are the specialists for sticky, dull and very light materials.The synchronous pair of screws prevents build-up on the screws during operation and an agitator running directly above ensures that the screws are filled evenly - the essential prerequisite for precise dosing. In addition, our TWIN series is also very suitable for small quantities of a few grams per hour due to the even product discharge.

TWIN20

Twin screw

with agitator

0,1 until 100 liter/h

- Small and light

- Easy to clean

DUPLO20

Loss-in-weight feeder

TWIN20 + BASIC platform scale

TWIN40

Twin screw

with agitator

until 1.500 Liter/h

- Large product room/ funnel

DUPLO40

Loss-in-weight feeder

TWIN40 + BASIC platform scale

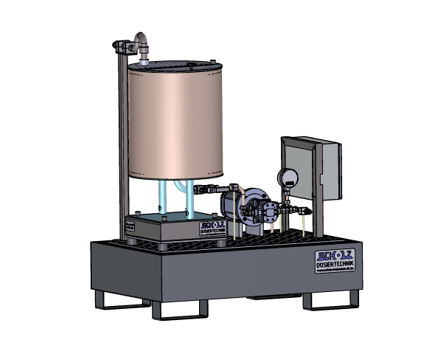

FLUIDS

Our LIQUI dosing stations are built individually according to your requirements. We select the appropriate pump technology based on the physical properties of the dosed substance (primarily viscosity and bulk density) as well as the process back pressure (bar): besides gear and diaphragm pumps, we also offer hose or piston pumps. We build the dosing station around this pump: mobile or stationary, including a refill pump and pressure hoses if desired. If necessary, we can also design the entire station in an actively heated version.

WEIGHING TECHNOLOGY

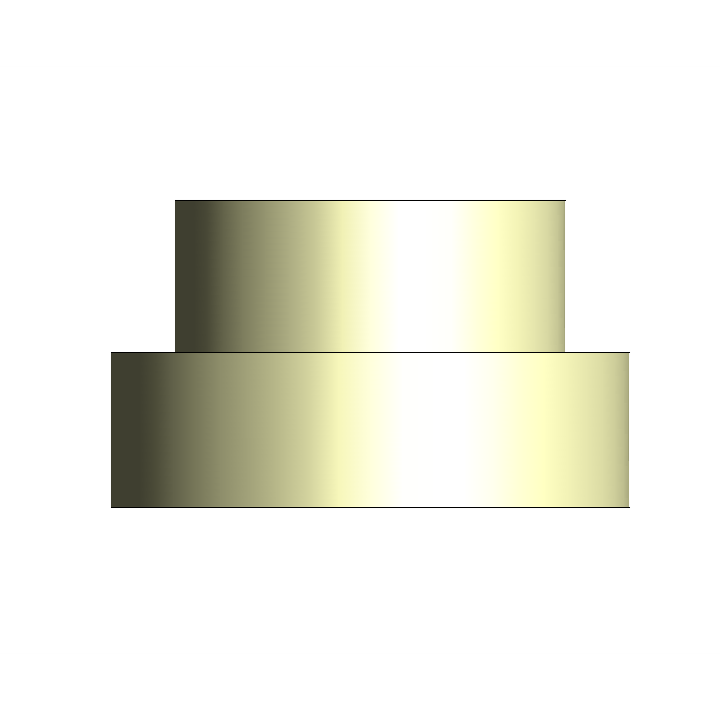

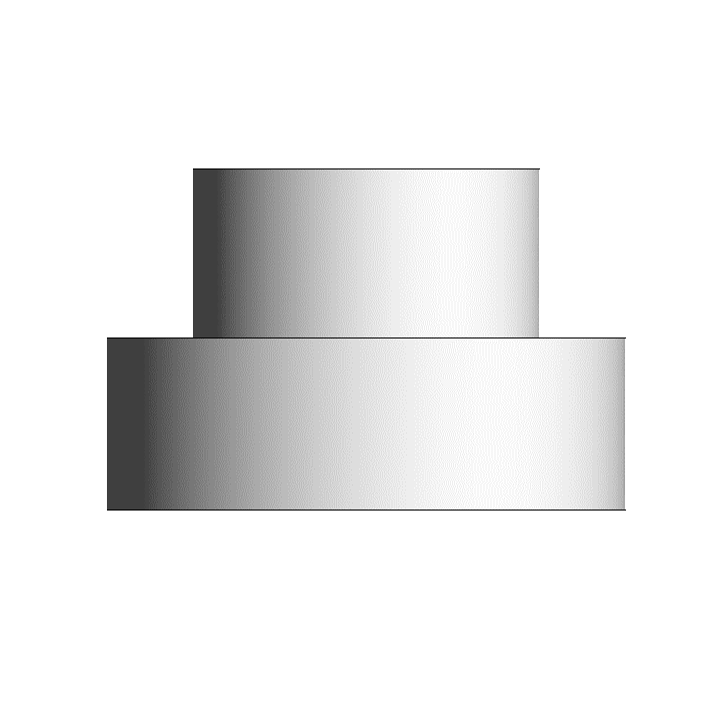

In order to switch from a volumetric to a gravimetric dosing device, the feeder is linked to a platform scale. All of our platform scales have an identical height. We offer two different measurement techniques, the PESA string technique and the strain gauge technique (DMS). Depending on your capacity requirements, the feeder will be linked to a SCHOLZ BASIC300, SCHOLZ BASIC400, SCHOLZ BASIC600 or SCHOLZ BASIC800.

PESA-STRING-TECHNOLOGY: The tension of a vibrating string is influenced by the load weight on the platform scale, which changes the vibration frequency. The weight is detemined from the change in the oscillation frequency. The technology is used for gravemtric feeders with SCHOLZ BASIC300, SCHOLZ BASIC400 und SCHOLZ BASIC600.

DMS-TECHNOLOGY: The measuring principle is based on the change in electrical resistance when suitable materials are stretched and compressed. The load on the platfrom scale thus causes a voltage change by which the weight is determined. The technology is used for batch as well as gravimetric applications with SCHOLZ BASIC700.

BASIC300

BASIC400

BASIC600

BASIC700

GRAVIMETRIC EQUIPMENT

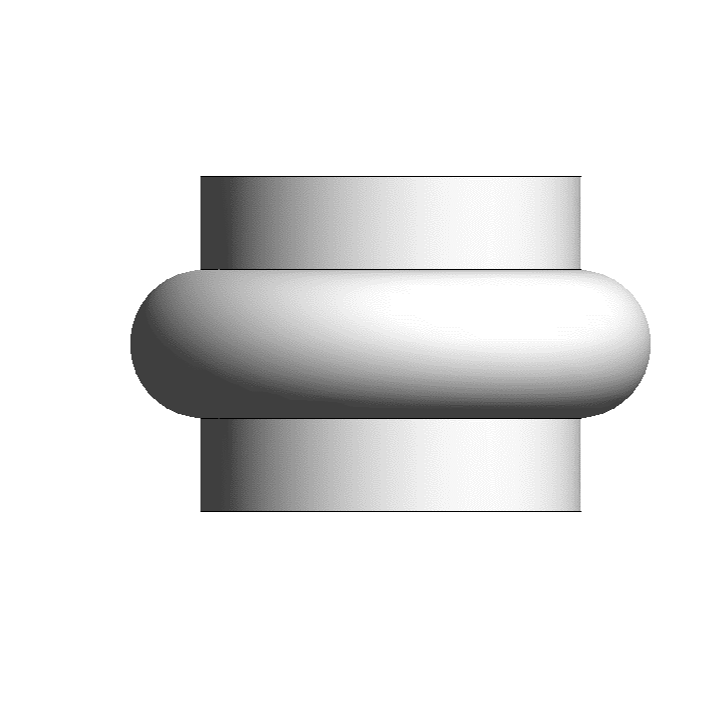

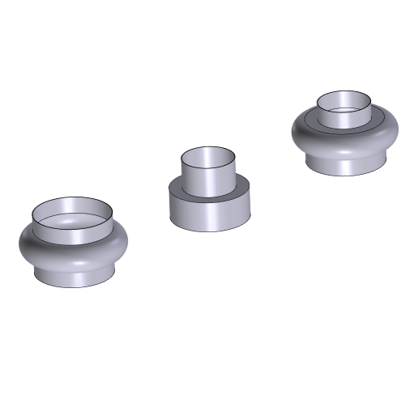

We offer accessories for gravimetric dosing devices. The folding and step bellows as well as the pipe caps, filter bags and hose clamps are particularly easy to maintain as they can be easily replaced.

OPTIONAL CERTIFICATIONS

Explosion-proof version

ATEX certified

Food-safe version

FDA - EC 19535/2004 certified

YOUR EXPERTS

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.